Articles & Videos

Read More

Read More

Built for People Who Respect Physics

When someone hears the name Burns Stainless, the takeaway should be simple—and uncompromising: this is where exhaust systems are built the right wa...

Read More

Read More

Top 10 Essential Performance Mods for an M8 Bagger

What actually works—and why order matters

The Milwaukee-Eight is a strong engine platform, but the biggest mistake riders make isn’t which parts ...

Read More

Read More

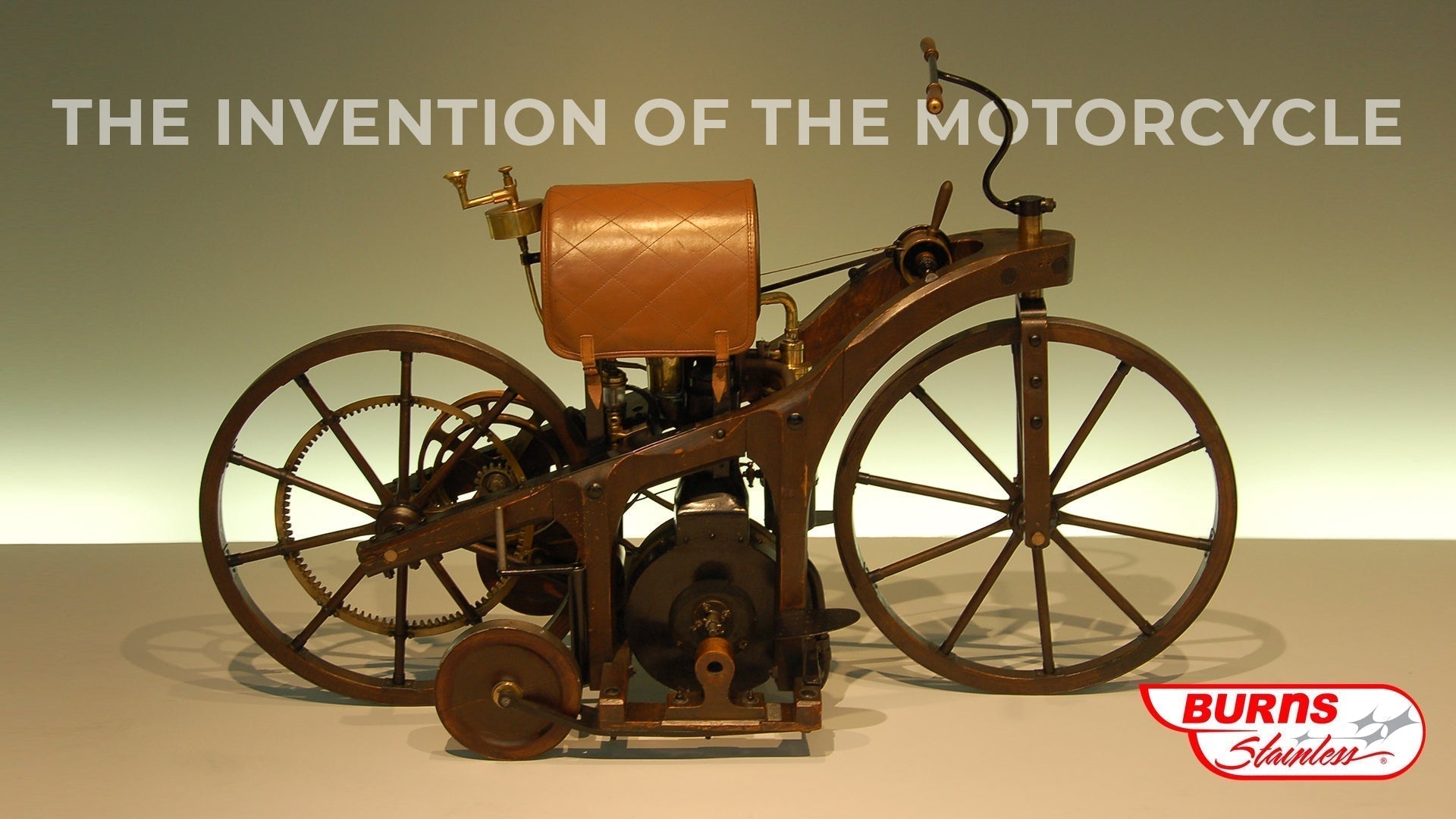

The Invention of the Motorcycle

How Engineering, Risk, and Performance Created Two-Wheeled Freedom

The motorcycle was not invented to be safe, comfortable, or practical.

It...

Read More

Read More

Chase French Runs Burns at his first Bagger Racing League series

We catch up with Chase French in the SpeedFarm paddock as he prepares his Harley M8 Lowrider for his first ever Bagger Racing League race. It is h...

Read More

Read More

Sin City Bagger Showdown: Burns Stainless Powers the Final Round of the Bagger Racing League Season 6

The Bagger Racing League Season 6 finale at Las Vegas Motor Speedway brought blistering speed, packed crowds, and Vegas-style celebrations. Burns Stainless exhausts powered Vincent Wilson’s 152 mph Pan America and rookie Chase French’s podium debut in the Sin City Bagger Showdown.

Read More

Read More

AMERICAN MADE? - We Answered.

This episode of Vincent Shorts we reach out to Cam over a Baggers and Bourbon. He had a video on his YouTube Channel that addressed the moniker of ...

Read More

Read More

Heat Issues? We Answered...

This episode of Vincent Shorts we reach out to Cam over a Baggers and Bourbon. He had a video on his YouTube Channel that had a lot of good points...

Read More

Read More

Meet Robbie Lane from Alloy Art

Pan America Racer Debuts at Born Free 16

From Custom Fabrication to the Racetrack

At Born Free 16, one bike drew serious attention: a full-tilt Ha...

Read More

Read More

Vince in Shorts - Born Free 16 Featured Builders Showcase

In this episode of Vince in Shorts we present more from Born Free 16. Part 2 from Born Free 16 features a look at the three bikes we sponsored pa...

Read More

Read More

Vince in Shorts - Born Free 16 Part One

In this episode of Vince in Shorts we are at Born Free Show 16 in Silverado, California. Vince tells a bit about the bikes and displays in our boo...

Read More

Read More

The Roar at Chuckwalla

We spent the weekend last month in the desert to support the racers at the Drag Specialties Battle of the Baggers first race of the season at Chuc...

Read More

Read More

Alex Palou wins the 109th Indianapolis 500!

The Indianapolis 500, one of the most recognized sporting events in the world. This year the Indy 500 is marked as the largest sporting event in th...