In Part 2 we discussed the importance of tube fitment when fabricating headers. This month, we will discuss techniques involved with back purging exhaust tubes. When heated to welding temperatures, alloys such as stainless steel and Inconel are prone to the formation of oxides if not shielded from oxygen present in the air. Technically known as "sugaring" or "noogies," these oxides will result in a poor weldment, characterized by a black, crusty appearance of the weld metal on the inside (root) of the pipe and an irregular root cross-section. Weld defects include lack of fusion to the base metal, root-pass cracking and incomplete penetration. Since it is most often impossible to see the weld root in an exhaust application, many poor fabricators may think "out of sight, out of mind." But this could not be further from the truth.

GTAW Figure 1or TIG welding provides a gas shield around the welding electrode to prevent the formation of these oxides on the front of the weld. In the same manner, a shield must be provided on the root, or backside of the weld to prevent "sugaring." The re are several techniques available including shielding the weld root: Weld-backing tape (Figure 1), Solarflux (Figure 2), and gas back-purging (Figure 3). Tape does not lend itself well to tubing, as it would not be possible to apply and/or remove the tape except possibly in the case of short 4" or 5" tubes. Solarflux is a powder that is mixed with alcohol (methanol, ethanol or iso Figure 3propyl) to form a paste. The paste can be applied with an acid brush onto the backside (inside) of the tubes prior to tacking. When the base metal is heated by the welding torch, the Solarflux paste crystallizes and forms a shield preventing oxygen from contaminating the weld. Solarflux B is an excellent option for stainless steel welding. Solarflux 1 is also available for high nickel alloys such as Inconel.

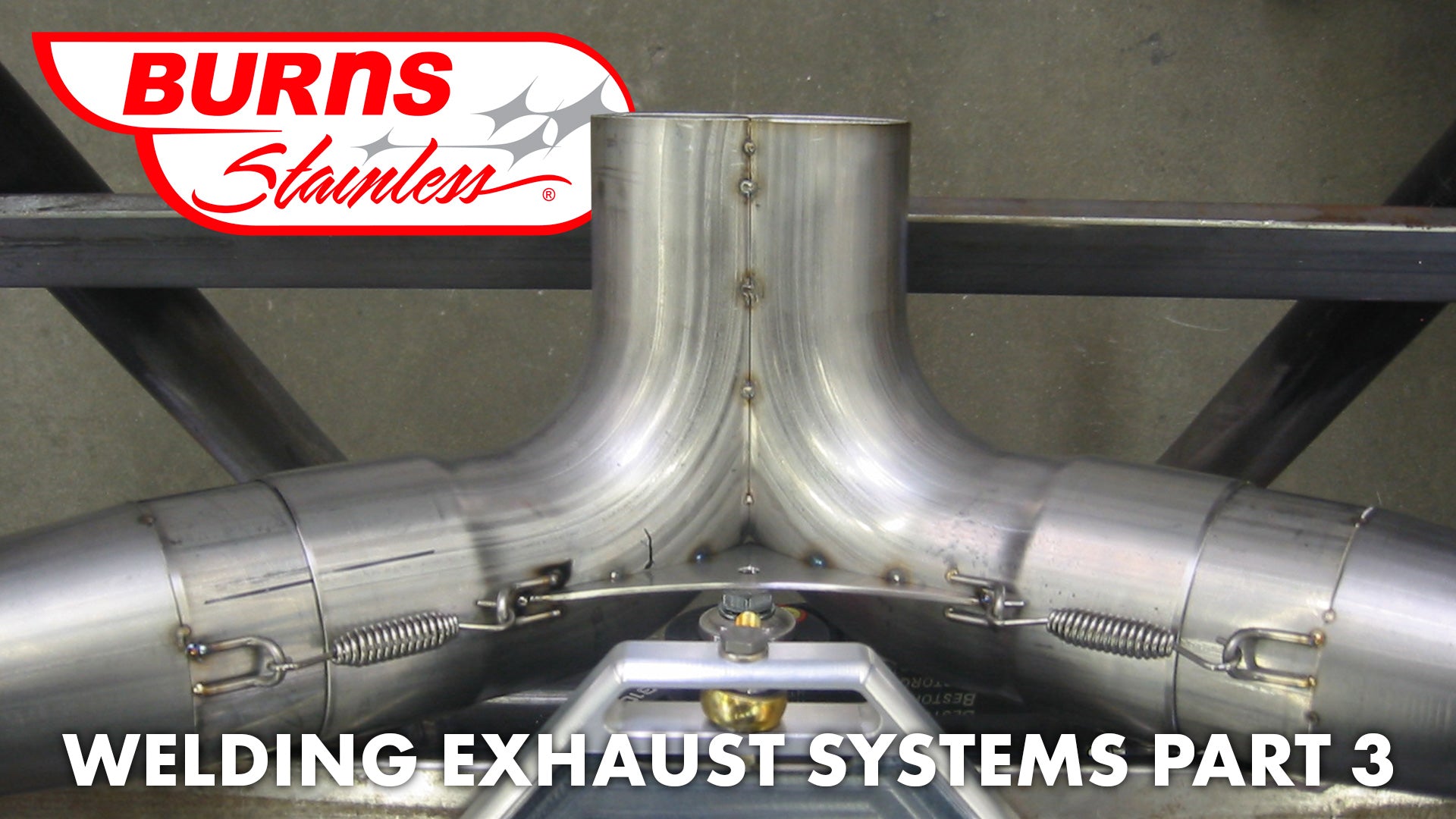

At Burns Stainless, gas back-purge is the preferred method of weld root shielding. Almost all stainless steel or Inconel welding done at Burns is back-purged with argon gas. Reasons include minimized tube preparation, easy availability of argon gas, and the fact that it provides strong and consistent weld quality. It would be difficult to duplicate the "Burns weld" using any other technique. At Burns, Solarflux is used for welding when back-purging is not feasible such as welding flat plates such as flanges or for some repair work.

Figure 4Back-purging requires an inert gas supply, a metering system and a gas dam system. The gas supply is typically the gas cylinder used for TIG shielding gas, typically argon. A back-purge metering system (Figure 4) is "tee'd" off the regulator and a gas line run to the gas dam. For welding exhaust tubing, rubber stoppers with holes make e Figure 5xcellent dams. For example, when welding a primary pipe, the stoppers would be placed at each end of the tacked together tube. The gas line is attached to one of the stoppers (Figure 5), and the other stopper left open (Figure 6). The shielding gas is metered into the tube until all the air in the tube is displaced with the inert gas. The gas should flow through the tube continuously during welding.

Figure 6

Weld the tube as usual. Before welding the last joint, it is a good idea to stop the purge-gas flow. The combination of heating the gas and eliminating one of the "leaks" can cause the stopper to blow-off the tube. Loud bangs are best avoided when under the welding hood!

When welding stainless steel and other exotic alloys, shielding the root of the weld is extremely important to insure the integrity and strength of the weldment. For welding exhaust tubing, inert gas-purging and Solarflux B are excellent choices for shielding. Next month, we will conclude the series on welding with a discussion of welding techniques and help you achieve that "Burns-look."