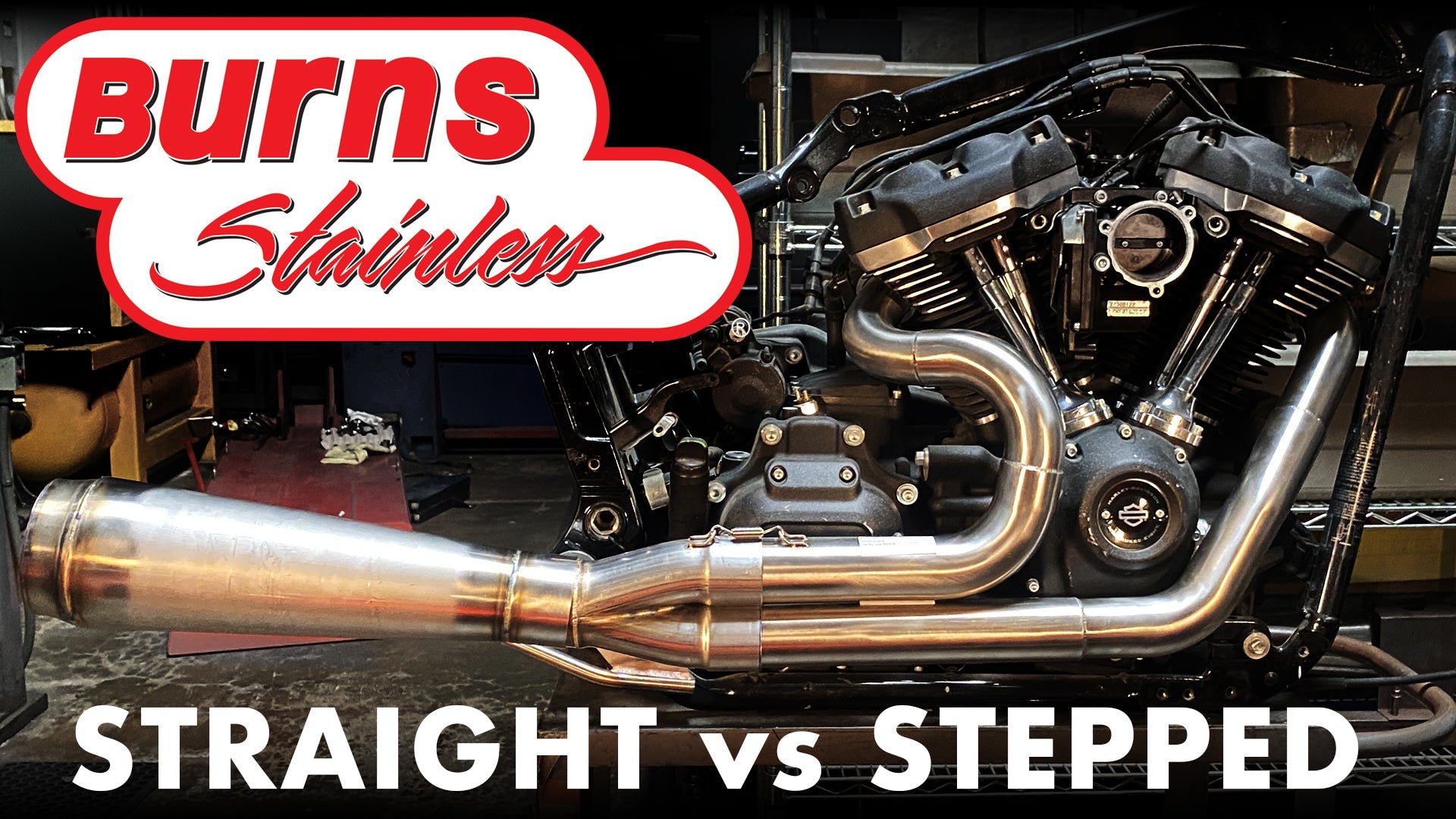

For decades Burns Stainless has been focused on building peak power throughout the power band. We are often asked the question “are stepped pipes better than straight pipes?” As is often the answer, “well, it depends.” Here we will help explain the difference and why it is important in your performance. The first question to ask yourself is “what do you plan to do with your vehicle?”. Are you building an all-out race car, or is it a weekend warrior?

The most critical design parameters for an exhaust header is the primary length, primary diameter, collector size and tail pipe size. Qualitatively, this is 95% of the game. Stepped headers will get you another 5% in terms of improved power band and power. I am not saying that you will see a 5% increase in power. This is an increase of 5% of the total of any performance gains from the entire exhaust system. Stepped header tubes are more difficult and more expensive to make than straight tubed headers. So, if you don't want to extract all the power available, then a straight tube header is going to be fine. Stepped headers is usually the best solution.

First, let’s review what happens in the header. As the exhaust valve opens after the power stroke, a pressure wave and a mass of exhaust gas flows from the cylinder into the header primary. The pressure wave travels at somewhere near the speed of sound and in the case of a straight pipe without a collector, the wave hits the end of the pipe, and a negative pressure (i.e. vacuum) wave reflects back up the tube. At the tuned rpm, the wave will enter the cylinder during the cam overlap period and will “suck” residual exhaust out of the cylinder and will help “pull” the intake charge to fill the cylinder. A straight open-ended pipe for each cylinder will create the strongest possible wave reflection from the end of the pipe. The problem is that when the rpm is off the tuned rpm of the pipe, the wave reflections can disrupt the cylinder scavenging and filling. The result is a narrow tuning range (i.e. peaky).

In a stepped tube header, the premise is that at each step increase, a negative pressure wave of less magnitude is reflected to the exhaust port. The reflections reduce the strength of the positive wave traveling down the tube resulting in multiple smaller reflection waves timed at different engine speeds resulting in a broader power band. Ideally, a constantly tapering exhaust primary tube would be ideal as you would distribute the reflected waves infinitely over the length of the primary tube.

So sounds like when money is no object, a stepped pipe is better, right? Well, no, not always. Remember what I said earlier. Two of the most important aspects is the primary and collector diameters. In many cases, engines have too large exhaust ports. This is especially true in antique and vintage engines. In general, exhaust tubes do not like to be reduced in diameter. If the exhaust port is larger than the ideal primary size, then building a stepped pipe will be make the primary too large, resulting in poor performance. We find that for well-developed modern race engines with properly sized exhaust ports, a 3-stepped exhaust primary is ideal.

Burns Stainless has the answer to find the right exhaust design to unleash the maximum potential of your engine. We built the Burns Stainless X-Design Parametric Exhaust Modeling Program specifically for racers who are looking to grab the most horsepower and torque possible out of their exhaust system. Simply fill out the extensive Race Engine Spec Form on our website as a perfect starting point for any header or merge collector project. We also have an extensive line of stainless steel Tubing and Bends as well as Mufflers and Collectors.

If you have any other questions on tuning your exhaust to your engine specifications give Vince or any of our expert performance engineers a call at Burns Stainless 949-631-5120 or email at Vince@BurnsStainless.com