"The Quality Is Remembered Long After The Price Is Forgotten." - Henry Royce

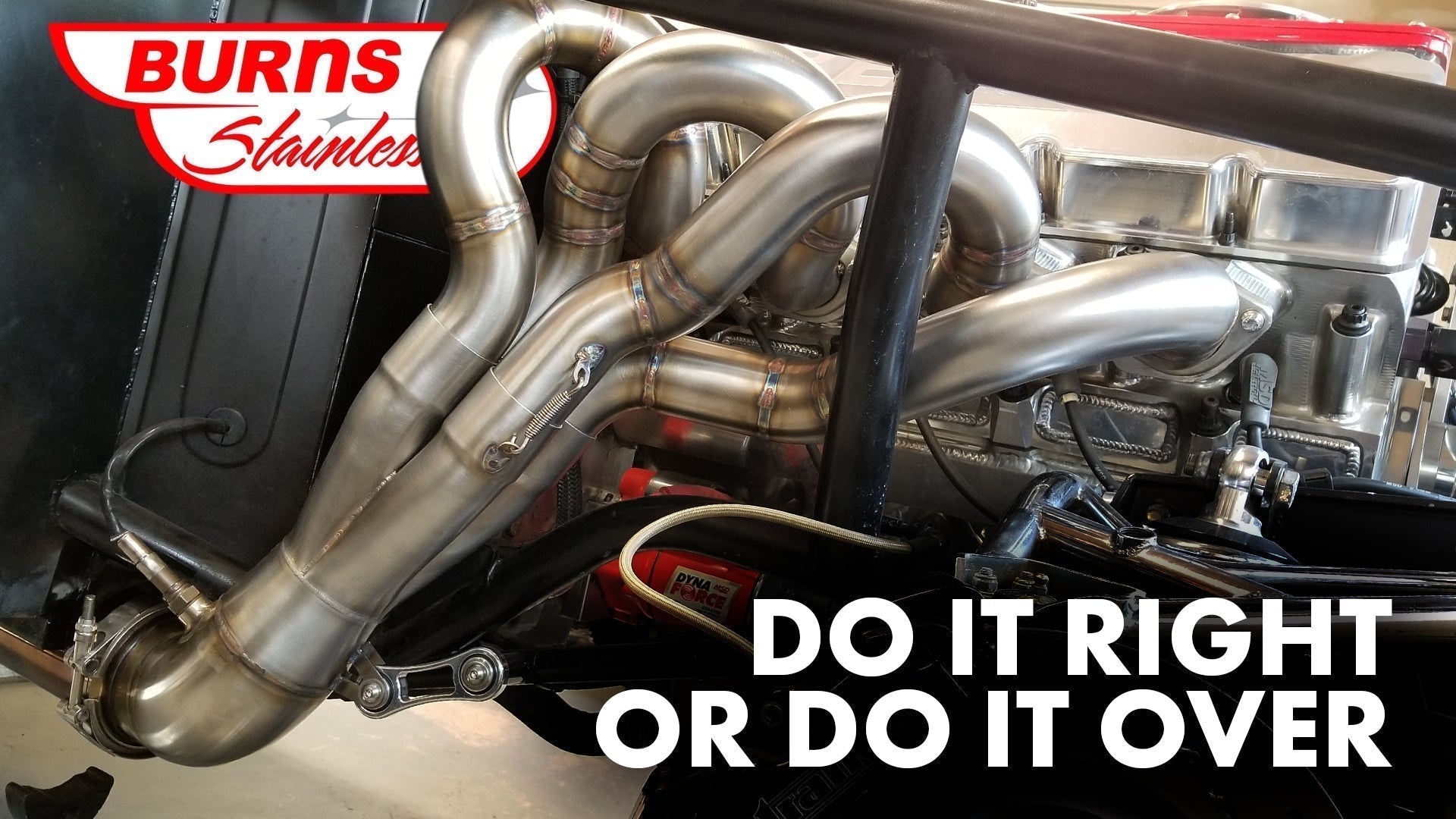

There’s a reason that serious fabricators, racers, and performance-obsessed riders turn to Burns Stainless. When the world feels chaotic and cutting corners looks tempting, we hold fast to the principle that built this company: relentless innovation backed by uncompromising quality. Plenty of suppliers chase cheap materials and cheap labor. That’s not us. That will never be us.

Burns Stainless exists to bring real performance value to your machine—whether you’re thrashing a Harley-Davidson M8 bagger, dialing in a custom race car, or crafting a precision motorcycle exhaust. Racers and builders don’t choose us because we’re cheap; they choose us because they refuse to do the job twice.

Motorsports isn’t just a hobby. It’s therapy. It’s family. It’s sanity. It’s one of the few places left where craftsmanship still matters, and where your passion pays you back every time you twist the throttle or stand on the gas.

That’s exactly why “Do it right, or do it over” hits so hard today.

Plan It Right the First Time

We’re here to answer your questions, talk through your build plan, and help you avoid those costly re-dos that drain your time and steamroll your budget. If you want to pull maximum power out of your exhaust system, the right tubing and the right bends matter—a lot more than most people think.

How Burns Stainless Saves You More

There will always be somebody cheaper. There will also be somebody more expensive. But tubing quality isn’t a mystery—it’s physics, materials, and craftsmanship.

Our stainless steel tubing is:

• U.S.-sourced and ASTM-certified, ensuring consistency and reliability

• Occasionally Canadian or Japanese when supply requires it—but always premium

• Bent with precise mandrel-controlled equipment operated by skilled technicians

• Produced on sophisticated machines capable of holding tolerances the cheap shops can’t touch

Mandrel bending isn’t a “set it and forget it” operation. Thin-wall stainless is unforgiving. Everything matters: mandrel placement, wiper-die rake, lubrication, pressure tuning, and die condition. Drift in any of these variables and you end up with oval, wrinkled, time-consuming bends.

You might save a few bucks at checkout, but you’ll pay for it in grinding, fitting, hammering, welding headaches, and lost performance.

In other words:

Cheap bends cost the builder more. Every. Single. Time.

Ovalized Bends = Lost Power + Lost Time

When a tube goes oval, the problems cascade:

• Cross-section shrinks → reduces exhaust flow

• Cut sections won’t mate → gaps everywhere

• Welding becomes a nightmare → impurities and warping

• Finished exhaust looks amateur → because the material fought you all the way

And if you’re quartering 180° bends or routing through tight spaces—like a Honda V4 or an M8 Bagger header—ovalization becomes a fabrication killer.

A Customer Story That Says It All

Dan Yoder, a fabricator building a Honda V4 exhaust, tried saving money by buying bends from “Company X.” After 25 hours of mock-up and $500 in material, he was staring at mismatched sections and ugly gaps.

He reached out to us with photos and frustration.

Customer Testimonial

Below is an experience from a customer named Dan Yoder who was building an exhaust for his Honda V4:

"So I started on a bike exhaust and got some bends from Company X because a friend of mine is good buddies with them. After spending about $500 and oh I'd say 25hrs of my time I got the first bank of parts mocked up...wasn’t paying too much attention to the fit of each section, more about mocking the path of the exhaust. Then I get closer to tack welding and notice how "ovaled" the bends are.

This is a V4 bike so the exhaust snakes all over hell and there are several sections where I took a 180 bend and quartered it because that's really the only way to make it work. Needless to say I was not happy with how the fit was when you turn the cut around on itself. There are actual air gaps on either side. I heard from a good friend and chopper builder that he only uses you guys and that I likely bought sh!%%y bends.

I’ve attached two pics above that show each opposing side of the fit up (couldn't get an accurate shot from one pic). If I were to re order my material from you guys can I expect a better fit up at the peaks of the bends? What I’m working with now will not only look sub-par when it is done but it will take forever to get each section formed right for welding....and lets not even talk about how much of a PITA welding those parts would be.”

Quality In = Quality Out

“To build a top-quality product, you have to start with top-quality materials.”

It’s not a slogan to us—it’s shop-floor truth.

Burns Stainless products aren’t for everyone. They’re for the builders who care about craftsmanship, performance, and long-term reliability. They’re for the racers chasing tenths, the fabricators who take pride in their welds, and the riders who expect their machine to answer the call every time they crack the throttle.

We don’t cut corners. We don’t cheapen our name. And we don’t ask you to settle.

Dan didn’t settle—and the photos of his V4 exhaust prove it.

Closing Thought

“It takes less time to do it right than it does to explain why you did it wrong.”

Burns Stainless is here for the builders who still believe in doing it right. Southern California, nationwide, and worldwide—we’re committed to giving fabricators the precision, performance, and reliability they deserve.

If you’re ready to build something worth remembering, start with the right materials.

Here are some photos of Dan’s handiwork. Now you sure couldn’t tell from these pictures that this was Dan’s first time to build an exhaust and weld stainless steel.

See what you can do if you have the right stuff! Are you committed to doing the best job possible? Check out our bends here