All Burns Stainless exhaust tubing is made in the USA and is mandrel bent to ensure smooth bends and maximum flow. Made for high end header fabricators, our exhaust pipes are easy to fabricate with, saving you time and money.

Don't settle for anything less, our top tier quality control ensures a consistent cross section throughout. The end result is a quality product that keeps exhaust velocity and flow at optimum levels.

“It takes less time to do it right, than it does to explain why you did it wrong.” - Henry W. Longfellow

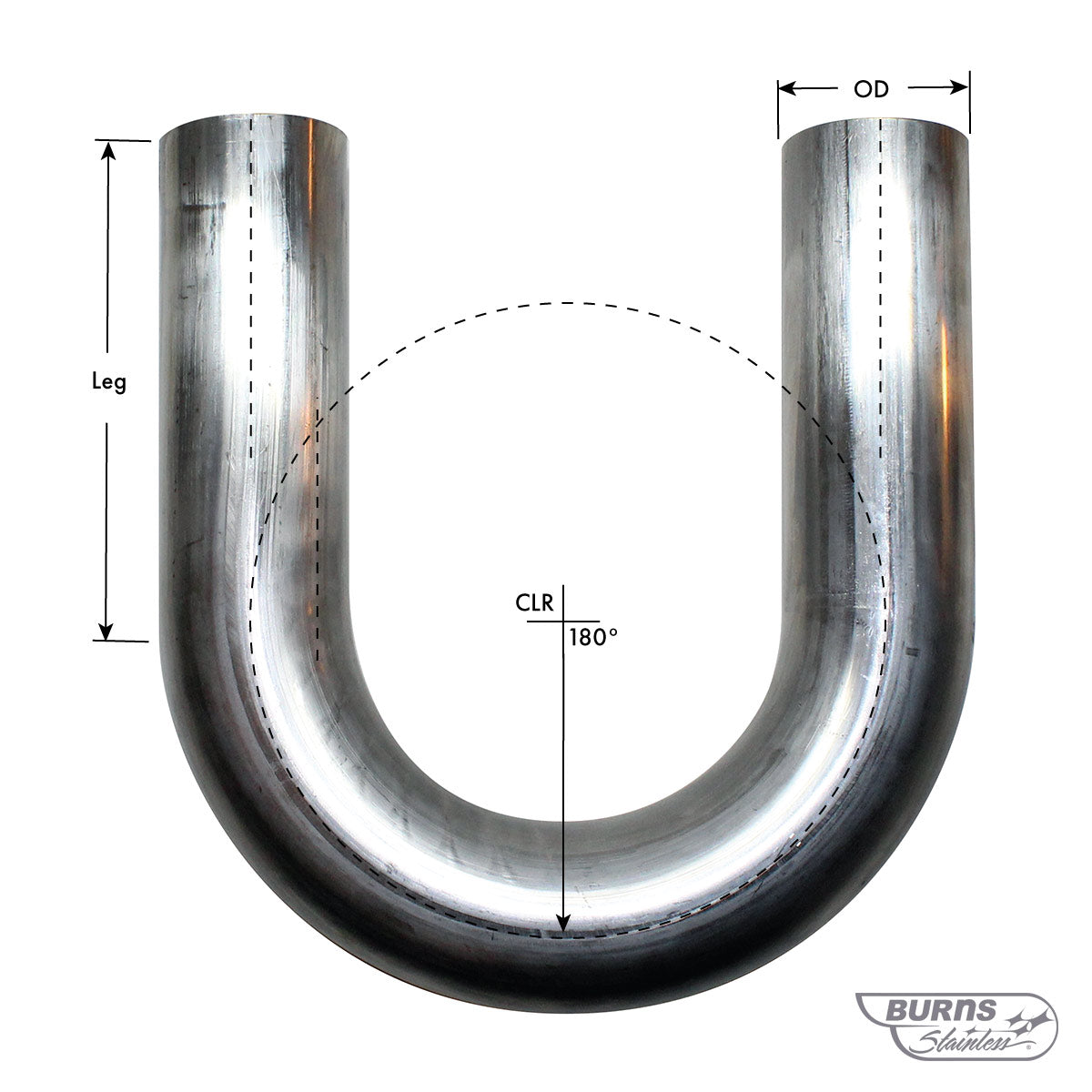

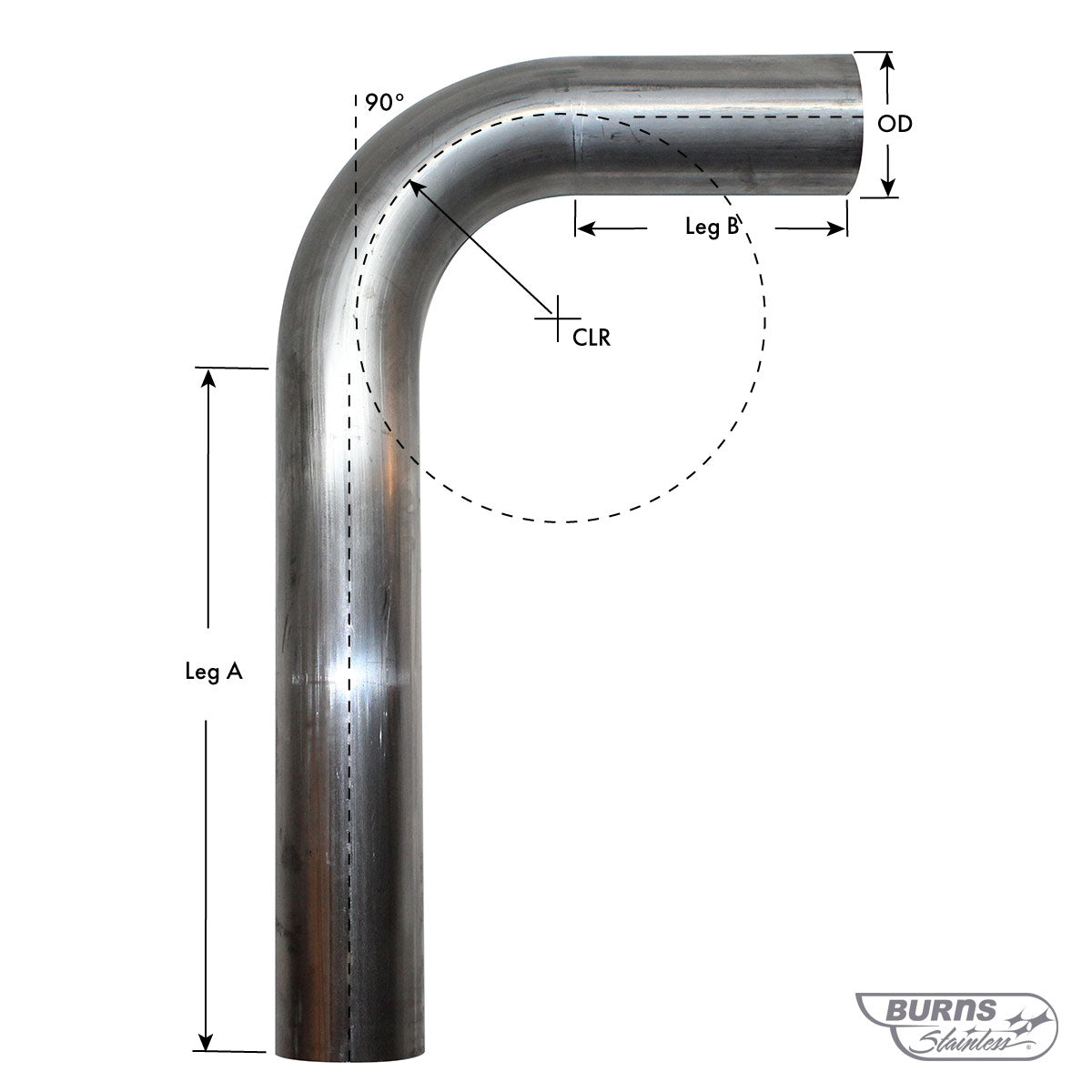

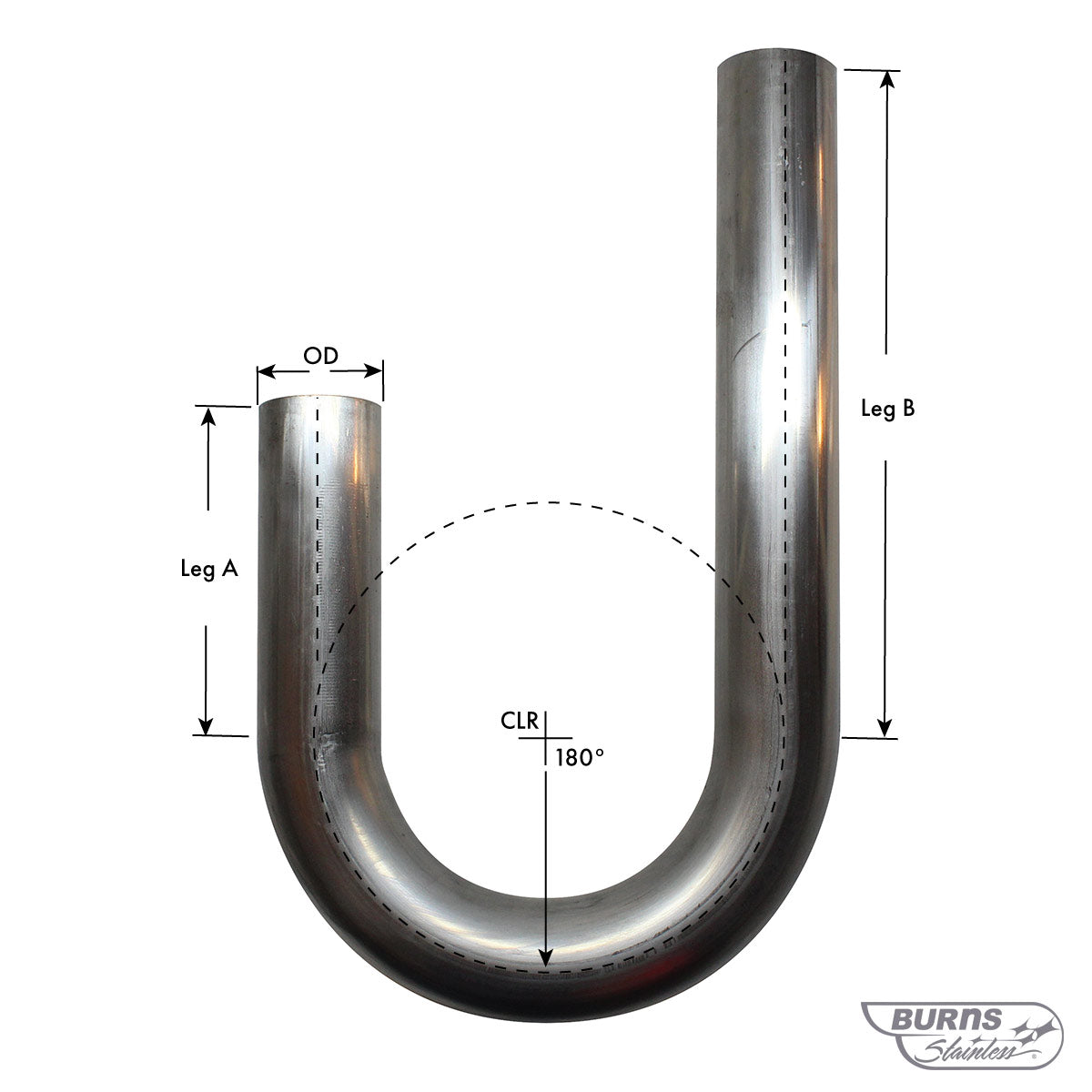

We are often times asked why our stainless mandrel bends and tubing is expensive compared with our competition. There are several reasons. We use U.S. sourced, ASTM certified tubing. We use the utmost care in the mandrel bending process. As you know, mandrel bending is a process where metal tubing is bent around a die on a hydraulic or electric machine using a “mandrel.” The mandrel is pulled through the inside of the tube in order to keep the tube cross-section round through the bend.

There are many variables in the bending process that must be carefully balanced and monitored in order to attain a bend that has a round cross-section and no wrinkles, especially when bending thin-walled stainless tubing. These include mandrel tool material and condition, placement of the mandrel at initiation of the bend, machine pressure settings and wiper-die rake, to name a few.

To assure that these parameters do not drift out of tolerance requires an alert operator and sophisticated benders, both of which are costly for us – but more importantly, saves you time and money in the long run.

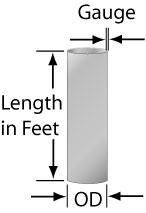

Find my Pipe