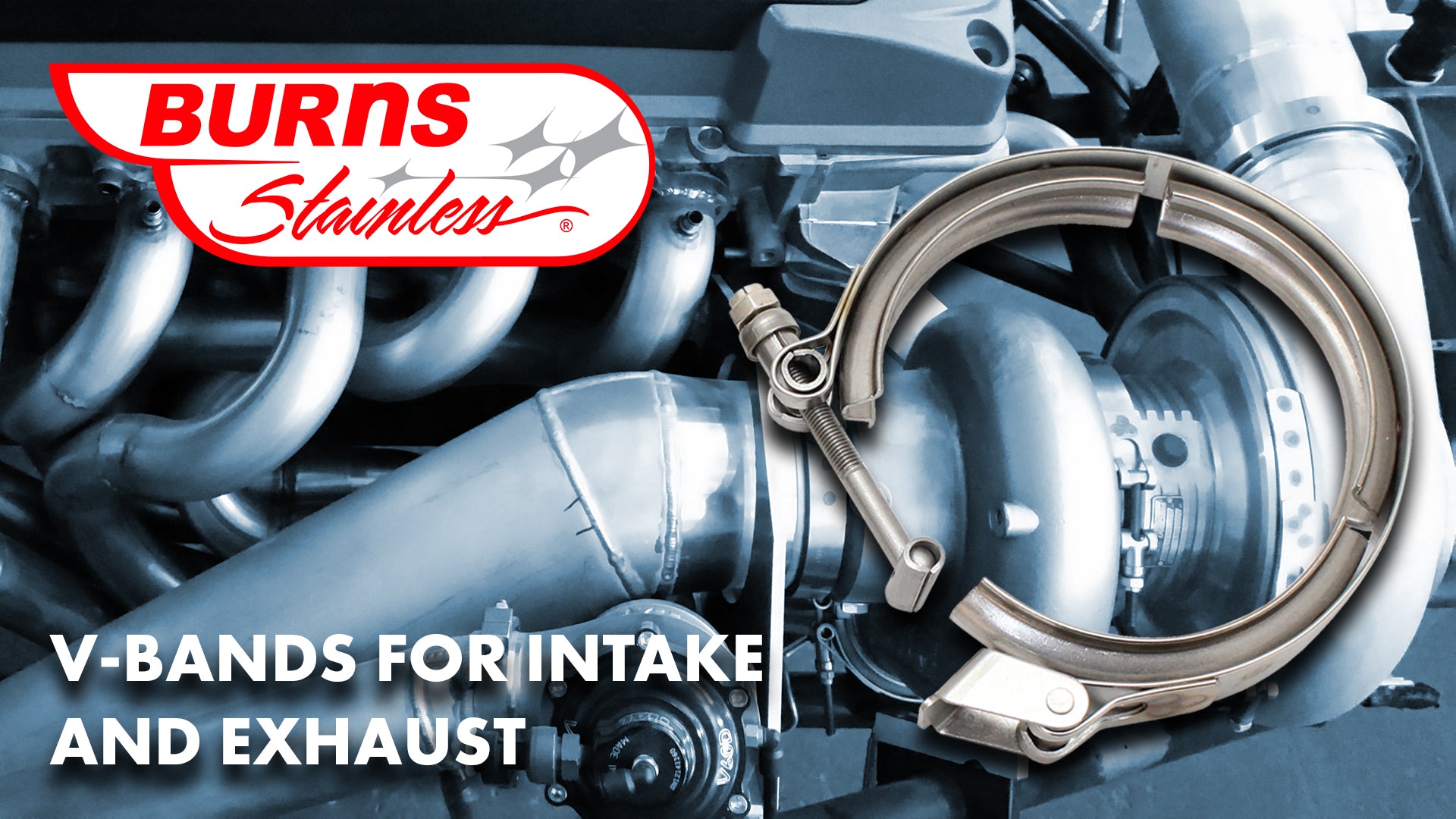

V-Band clamps and flanges make for ideal tubing connections in exhaust applications, especially when the connection requires frequent disassembly. Used extensively in space vehicles and satellite launch systems, they have proven themselves in racing applications including high pressure turbo applications.

The V-band connection gained popularity in CART racing and is the preferred connection for many turbo-housings. They are also an excellent choice for normally aspirated exhaust and for intake systems.

Compared with 2-bolt or 3-bolt flanges, Vband connections are typically lighter and are quicker and easier to take apart. They are also economical when compared to the 2- and 3-bolt flanges. The Vband connection also requires a small fitment envelope as compared with multi-bolt flanges. The design of the V-band clamp applies uniform force around the flange maximizing the seal potential of the flanges (see Figure 2). The cross-section design of the retainer is shown in Figure 3. The retainer angle, normally 40 degrees provides for an 8.6-to-1 mechanical advantage. In other words, when the V-band retainer bolt is tightened the clamp applies a radial force and an axial force pressing the flanges against each other providing an effective seal. Once tightened, friction between the flanges and V-retainer actually helps reduce the load on the bolt and clamp.

For a detailed cross section of the V-Bands, click on either Figure 2a, or 2b.

There are two types of retainer styles (Figure 4), V-band couplings and Vband retainers, though both styles are typically called V-band clamps. T he V-band couplings are made from multiple V-segments spot-welded to a sheet-metal band, whereas the V-band retainer is made from a single V-segment welded to a band. The advantage of the V-band coupling is that there is less distortion on the flange if the band is over-tightened. The V-band coupling design is ideal for racing applications where getting to the starting line is often a higher priority than properly torquing a V-band clamp, and is the style Burns Stainless carries. Another great feature of our V-band couplings is the quick-release clamp design (Figure 5). The over-center style, quick-release allows for easy and quick installation of the clamp. To remove the clamp, the nut is backed off just enough to loosen the latch which is moved out of place quickly by hand and the clamp removed. To install, the clamp is put in place and the latch secured over the T-bolt and then the nut is tightened. The over-center design ensures that the latch will not come apart when used.

In general, there are two types of Vband flanges available: Bulge formed and machined. The bulge formed flanges are formed from a tube that is “bulged” then collapsed to form a flat flange (Figure 6). Machined flanges, as implied, are machined from metal stock. The bulge-formed flanges are “self-energizing” and normally do not require a flange for most exhaust applications. This is do to the "springback" in the rolled-over face of the flange. Machined flanges should be used with a gasket for most connections. Also, the bulge-formed flanges are typically lighter than machined flanges. An added benefit is that the thinner section of the flange is closer in thickness to the base tube resulting in a more compliant joint, minimizing stress cracking in the weld.

Burns Stainless offers stainless bulge-formed exhaust flanges that are made from 321SS to MIL-Spec XX. We find that these flanges are superior for most exhaust applications including turbo-charged applications. Many fabricators say they like machined flanges because of the machined step found on some flanges. This is a great feature to help index and install connections, and it is easily replicated using the bulge-formed flange. By sliding the flange over the OD of a tube and past the face (Figure 7) a step can be formed resulting in a male/female type joint. This method also helps minimize shear and/or moment loading from the Vband retainer resulting in a stronger joint.

For aluminum tubing, Burns offers aluminum flanges machined from 6061-T6 alloy. The flanges are designed for an o-ring seal to prevent leaking. These are an excellent choice for most applications. If axial and or angular flexibility is required, Burns also offers a full line of Wiggins connectors.