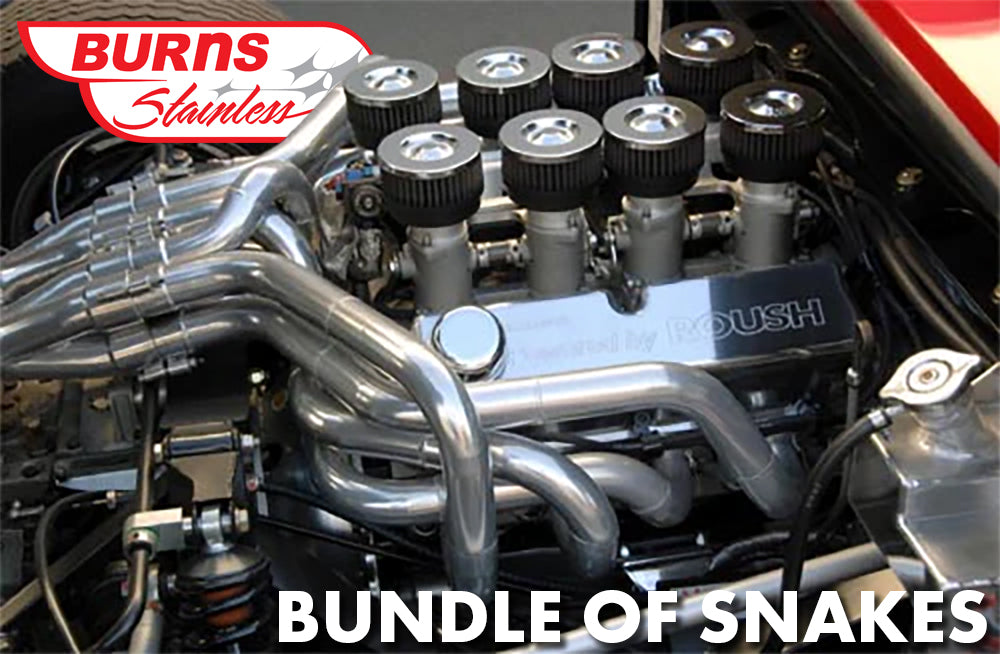

Many of you have seen the so-called “bundle-of-snakes” headers on the infamous Ford GT40s of the late sixties, but you might wonder.

Are they still relevant today?

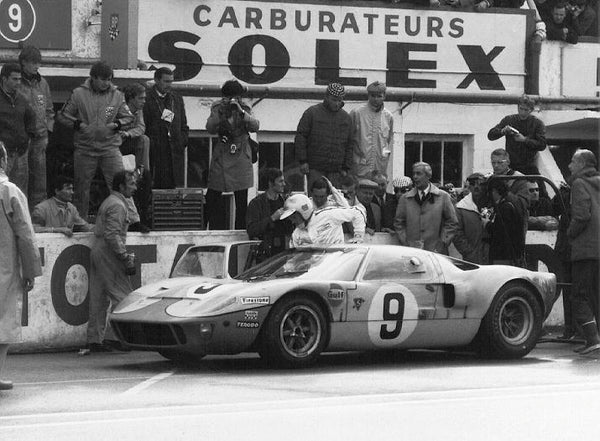

Those beautiful works of art built by English craftsman on the Lola-designed chassis where two tubes from each bank of the V-8 are crossed over the engine to collect in 4-1 collectors with opposing tubes.

What was the purpose of these tangled spaghetti-like devices?

Most modern V-8s have what is known as 90-degree cranks (aka crucified cranks, bent cranks, cross-plane cranks) wherein the cylinder firing order is such that two cylinders on each bank fire consecutively as opposed to alternating banks.

The purpose of the 90-degree crank is to minimize vibrations inherent to “flat-plane” cranks.

Some racing and high performance engines including Ferraris use a flat-plane crank to optimize the intake and exhaust processes, accepting the additional vibrations.

GT40 at Le Mans

So what’s the problem with these 180 degree headers?

The problem is that for a conventional 4-1 exhaust header, the separation between two firing (or exhaust) impulses is 90 crank degrees in each collector versus 180 crank degrees for a flat crank engine.

This gives the engine that inherent “American V-8” exhaust burble, but also causes a “crowded” condition in the collector when two exhaust pulses, separated by only 90 crank degrees are trying to exit through the collector.

To accommodate this, the collector for a 90-degree crank motor must be larger than for an “all-other-things-being-equal” flat-crank motor, thereby losing some low and mid-range torque.

The “bundle of snakes” design collects two tubes from each bank into a single 4-1 collector resulting in four evenly spaced exhaust pulses as in the flat-crank header design.

A broad power band is inherent to the 180 degree header design due to the smaller collector size. This was a great idea, and I am sure contributed to the success of the GT40

“Back-in-the-day.”

Great look, but is the performance effective today?

Often times I am asked to specify a 180 degree header design, usually for a replica GT40 or Pantera. Though I think it is a great “look” and if I was building a street GT40, would likely choose the design for historical purposes, the truth is, it is often not the best design from a performance standpoint.

Why you ask?

Engine speed.

The V-8s that ran in the late sixties were relatively low rpm engines. Due to packaging, that is, fitting the collectors behind the engine, the shortest primary lengths usually possible is around 36”.

This primary length is good for a motor with a useable rpm range of 4500-6000. And wouldn’t you know, a small-block “HiPo” engine of the day made around 300 hp at 6,000 rpm – perfect.

Today, some GT40 replica builders fit NASCAR Sprint Cup-derived engines built by the likes of Roush Yates Engines that make power at 8000 rpm+, dictating a header length closer to 28” or shorter.

Running a 180 degree “bundle-of-snakes” header would result in a few ponies left on the dyno room floor.

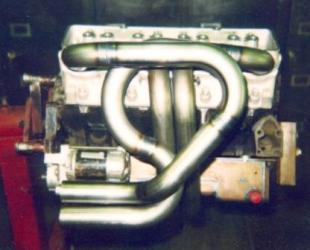

What we made working with a NASCAR Cup engine builder.

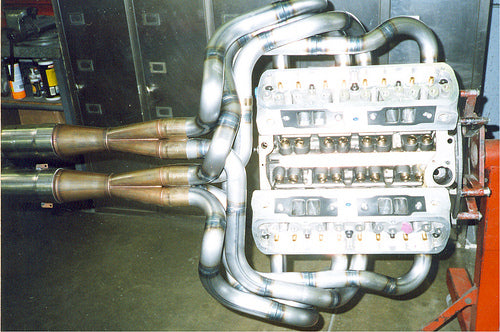

As the adage goes, “there is more than one way to skin a cat.” Several years ago, Burns Stainless was working with a NASCAR Cup engine builder to develop a 180 degree header (pictures above) that would work with a stock car.

The design shown in these pictures was developed that crossed the tubes under the engine. A special dry-sump oil pan was designed for the necessary clearance.

Initial testing was promising, but as it goes in racing, rule changes made the header illegal for NASCAR.

The last photo shows a header we built for Caldwell Development for a Reynard chassis Lemans Prototype powered by a restricted Dodge V-8.

Because of the restrictor, the engine rpm was limited making it an ideal application for the 180 degree header layout.

So what can you do to get more performance?

Though the use of 180 degree headers is limited to a few mid-engine low-rpm cars, or high-budget builds with custom oil pans and bodywork, you can still maximize your exhaust systems by properly engineering your exhaust manifold for your engine and application.

Properly engineered, an exhaust can be as, or even more effective, than these early 180 degree designs.

Our completely custom engineered header collectors combine high flow and high velocity to increase and broaden an engine's torque curve all the way to the horsepower peak and beyond.

Burns currently offers hand finished, high quality fabrication 2-1 collectors, 3-1 collectors, and even 4-1,5-1, 6-1 merge collectors.

The first step in this process is to complete the race engine specification form and send it to Burns Stainless for a custom exhaust design.”